Introduction of US UL certification standards for LED lighting products and operation guide for UL certification process

Although Edison of the United States invented the light bulb, the development of light bulbs has developed rapidly in China in the follow-up century. The former country of lighting fixtures is no longer the United States. Now our Chinese exports of lamps account for an amazing 70%. Basically, they are exported to European and American markets. It is self-evident that China is now a major country in the manufacture of LED lamps and other lamps. Then the lamps are exported to the United States. One of the most important certifications is UL certification.

Everyone knows that the UL certification in the United States is almost the national standard of the United States. UL is the most important maker of the American national standard. The UL standard in the United States is the same as the GB in China. The lamps have the Chinese national standard in China, so in the United States There is the UL national standard in the United States (UL153 standard / UL1598 standard / UL1993 standard / UL8750 standard), and one of the other reasons why the US UL certification is so popular in the United States is that American buyers are buying products with the UL certification mark. When you buy a product, you can get a lot of preferential policies when buying insurance, and the "Electrician Act" of the United States also clearly requires that some products need to obtain the UL certification mark. These are also some of the main reasons why related UL certification products are popular in the US.

UL certification has many standard requirements for LEDs and other lamps and lighting products in the standard requirements. Specifically, there are corresponding standard requirements in the housing, structure, drive power, wiring, and use environment.

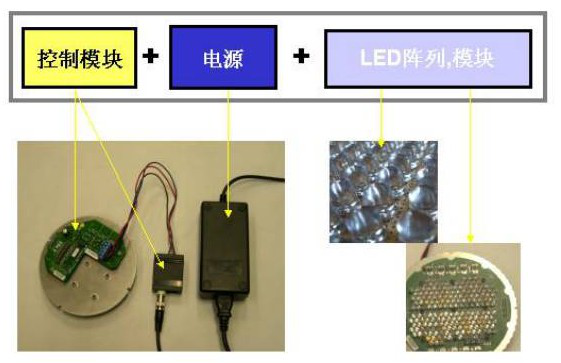

The electrical system of LED lamps is mainly composed of three major components: control module, power supply, LED array, and module. The structure of common LED modules: LEDs, PWB, resistors, capacitors, inductors and other components.

The UL certification standards define which materials can be used as lamp housings:

1. The sheet metal and extruded aluminum material meet the thickness in the UL standard;

2. The thickness of the cast metal meets the UL standard;

3. The plastic material meets:

① 5VA flame retardant rating (UL 1598 lamps)

② Suitable temperature class

③ Passed some mechanical tests and other parameter requirements in the UL standard.

And the following parts need to be provided with a housing:

1.Wire connector

2.Open core and enameled wire components (transformer, ballast)

3. Electronic components such as capacitors and resistors

4.Internal wire (AWM) or terminal block

5. Other arcing live parts, switches, etc.

Under the UL certification standard, there are three use environments for LED drivers:

1. Dry (There is not often moisture, but it can be occasionally entered, with ventilation holes and the like to prevent the accumulation of moisture. Generally located inside the building.)

2, Damp (often where moisture enters, and there may even be condensation of water vapor, such as under the eaves)

3. Wet (can be directly exposed to rainwater, where water can drip, splash or flow, such as street lamps)

So what are the following standards for LED lamps and lighting products in the US UL certification? The following are introduced one by one:

1.Standard for fixed lamps-UL1598 standard

Covered luminaires include branch circuits used in non-hazardous areas and installed below 600 V. Basically, almost all the permanently-connected luminaires on the market, which are not applicable to other special luminaire standards, ranging from recessed lights, wall lights, ceiling lights, to street lights, can be considered as belonging to the scope of this standard. The content of the standard includes: general requirements, mechanical structure, electrical structure, supplementary requirements for incandescent lamps, supplementary requirements for fluorescent lamps, mechanical testing, electrical testing and other requirements.

2.Standard for mobile (portable) lamps-UL153

Covered luminaires include those used for work or ambient lighting, and plugged into a branch circuit labeled 120 Volts, 15 or 20 Amps via a power cord plug. Basically, as long as the luminaire uses a power cord with a plug and is not applicable to other special luminaire standards, it basically belongs to the scope of use of this standard.

3.Used for self-ballasted lamp and its adapter-UL1993 standard

UL 1993 is a three-in-one standard jointly issued by the United States UL, Canadian CSA, and Mexican ANCE. It is also a US national standard approved by ANSI. UL 1993 covers self-ballasted lamps with adapters for rated input voltages from low voltages up to 347V, with their own caps. The self-ballasted fluorescent lamps (energy-saving lamps) and their adapters, LED bulbs, LED tubes and other LED light source products leading to the North American market are evaluated by UL 1993.

4.Supplementary standard for LED lighting components-UL8750 standard

When the light source and LED are LEDs, the LED components need to be evaluated with UL8750.

The above four standards are closely related to three major dangers: electric shock, fire, and mechanical injury. In layman's terms, a luminaire that does not cause electric shock to American consumers, does not cause a fire, and does not cause any mechanical damage to American consumers, is a standard luminaire that meets UL certification. UL-certified LED lamps and lighting products can be marked with the UL certification, which has won the trust of American consumers.